Global

Jun 27 , 2025

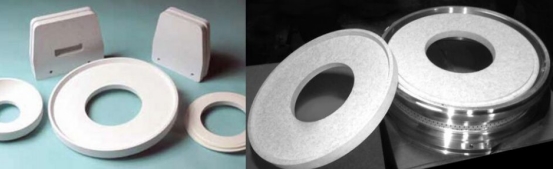

Calcium silicate transition plates, often referred to as T-plates, play a critical role in the aluminium casting process, particularly in vertical direct chill (VDC) and horizontal direct chill (HDC) casting machines for producing billets and ingots. They are essential components that ensure a smooth, controlled flow of molten aluminium into the mold and contribute significantly to the quality of the final cast product.

In VDC and HDC casting, molten aluminium flows from a holding furnace or launder into a mould assembly. The T-plate is strategically positioned at the interface between the molten metal delivery system and the mold cavity. Its primary functions include:

1. Controlled Metal Entry: The T-plate defines the initial shape and entry point of the molten metal into the mold. It ensures an even and laminar flow, minimizing turbulence and preventing air entrapment, which can lead to defects like porosity and inclusions in the final billet or ingot.

2. Thermal Management: Calcium silicate is an excellent insulator. The T-plate's low thermal conductivity helps to control the rate of solidification at the top of the billet/ingot. This is crucial for preventing "cold shuts" (incomplete fusion of molten metal) and ensuring a uniform microstructure as the metal solidifies.

3. Non-Wetting Properties: Calcium silicate materials are designed to be non-wetting by molten aluminium. This prevents the molten metal from sticking to the plate, allowing for clean separation and minimizing metal build-up and dross formation, which can otherwise contaminate the casting.

4. Minimizing Defects: By providing a smooth, non-reactive surface and controlling flow, T-plates significantly reduce the occurrence of surface defects, internal cracks, and segregation in the cast product.

5. Durability and Longevity: Given the high temperatures and corrosive nature of molten aluminium, T-plates are engineered to be highly durable, resistant to thermal shock, and have a long service life, reducing downtime and maintenance costs.

6. Precision Machining: They are typically precision-machined to tight tolerances, ensuring a perfect fit within the casting machine assembly and contributing to the dimensional accuracy of the cast billet or ingot.

The inner structure of calcium silicate T-plates is engineered to provide their unique combination of properties:

Calcium Silicate Hydrates (C-S-H) Matrix: The fundamental component is a matrix formed from calcium silicate hydrates. These are crystalline or semi-crystalline compounds of calcium, silicon, and oxygen, often formed through a hydrothermal curing process (reaction of lime and silica with water under heat and pressure). This matrix provides the base refractoriness, thermal insulation, and chemical stability.

2. Reinforcing Fibers: To enhance mechanical strength, toughness, and resistance to thermal shock, the calcium silicate matrix is typically reinforced with fibers. The two most common types are:

o Carbon Fibers: These provide excellent strength, thermal shock resistance, and good non-wetting properties. Carbon fiber reinforced calcium silicate plates are often preferred for applications requiring high durability and resistance to fracture.

o Glass Fibers: Glass fibers also contribute to strength and thermal stability.

3. Porous Structure: The material often exhibits a fine, uniform, and slightly porous structure. This porosity contributes to its insulating properties by trapping air within the material.

4. Binders and Additives: Various binders and specialized additives are incorporated during manufacturing to optimize properties such as:

o Improved Machinability: Allowing for precise CNC machining into complex shapes.

o Enhanced Non-Wetting: Further reducing molten aluminium adhesion.

o Reduced Shrinkage: Minimizing dimensional changes at high temperatures to maintain fit and function.

o Pseudoplastic Behavior: Some advanced carbon fiber reinforced calcium silicate materials are designed to exhibit "pseudoplastic fracture behavior," meaning that when a crack initiates, it propagates in a controlled manner (often with fiber pull-out) rather than leading to a catastrophic brittle failure. This increases the material's toughness and extends its service life.

5. Homogeneous Composition: A uniform distribution of the calcium silicate matrix and reinforcing fibers throughout the plate is crucial for consistent performance and to prevent localized weaknesses.

In essence, calcium silicate transition plates are advanced refractory materials designed to precisely control the flow and solidification of molten aluminium in direct chill casting, ensuring high-quality, defect-free billets and ingots through their unique composition and engineered inner structure.