Global

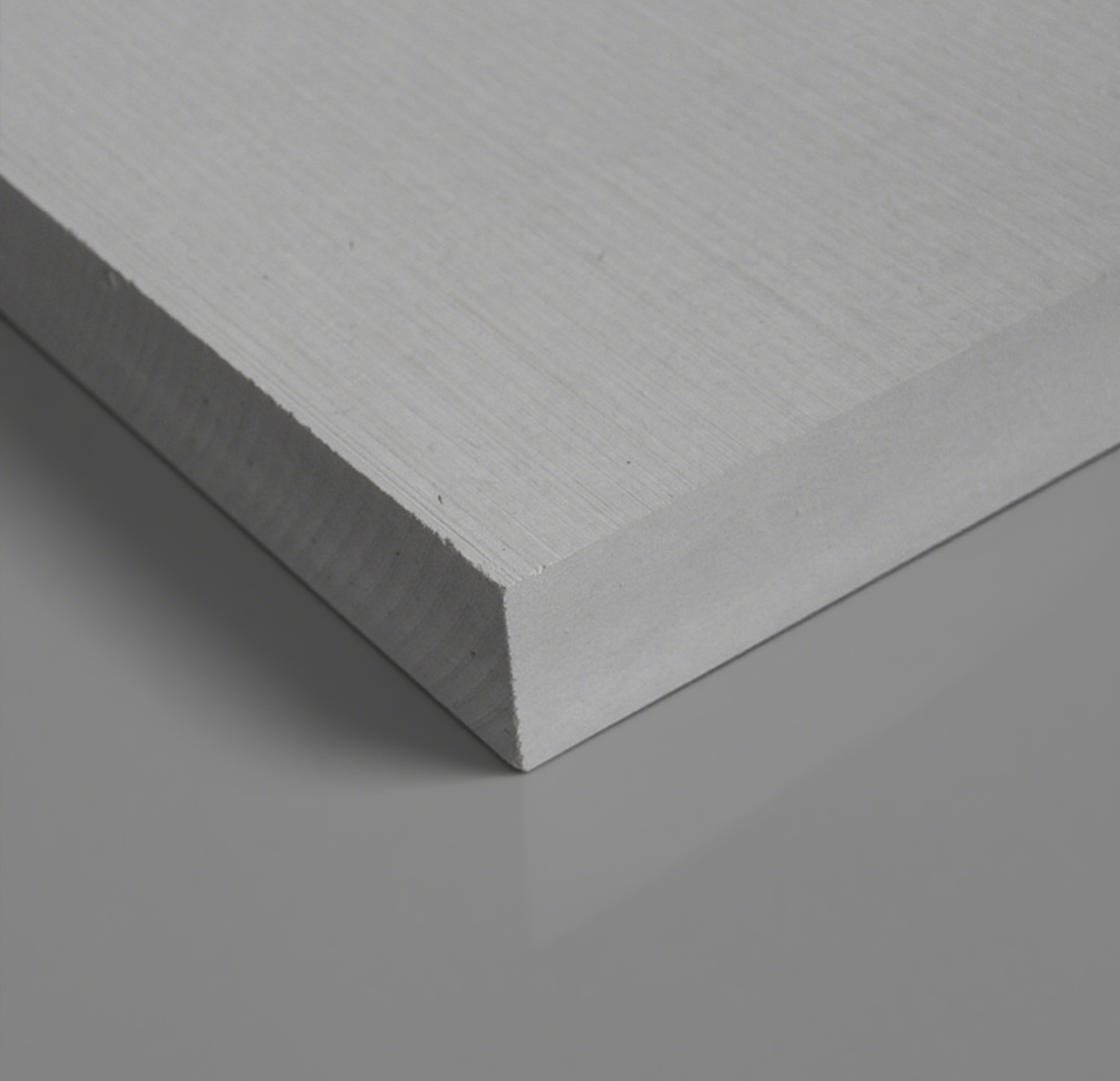

Primarily, it's used in rolling stock (trains and trams) for passenger comfort by maintaining internal temperatures and reducing energy consumption for heating and cooling. Additionally, specialized insulation can be found in infrastructure components, such as reducing thermal expansion and contraction in rails and bridges, and in noise and vibration dampening systems. The industry demands materials that are not only effective insulators but also lightweight, fire-resistant, and durable enough to withstand the rigors of constant use and varying environmental conditions.

Key characteristics for thermal insulation in the railway industry include:

Fire Safety: Strict adherence to fire safety standards for passenger safety is paramount.

Lightweight: Minimizing added weight to rolling stock for energy efficiency and performance.

Durability and Vibration Resistance: Withstanding constant movement and vibrations without degradation.

Thermal Efficiency: Maintaining comfortable internal temperatures and reducing energy usage.

Moisture Resistance: Preventing water absorption, which can compromise performance and lead to corrosion.

Noise and Vibration Damping: Some insulation materials contribute to a quieter and smoother ride.

Ease of Application: Facilitating efficient installation in manufacturing and maintenance.

Longevity and Low Maintenance: Ensuring a long service life with minimal upkeep.