Global

Thermal insulation and refractory materials are essential for efficient and safe glass melting operations. They ensure high temperatures are maintained, minimize heat loss, and protect furnace structures from the extreme conditions within. These materials find application in various areas of the glass industry:

Furnace linings: Protecting the furnace shell and containing the molten glass.

Crown insulation: Reducing heat loss from the furnace roof, improving energy efficiency.

Regenerators: Storing and releasing heat from exhaust gases, preheating combustion air.

Melting tanks: Containing the molten glass at high temperatures.

Forehearths: Conditioning the molten glass before it is formed into final products.

·

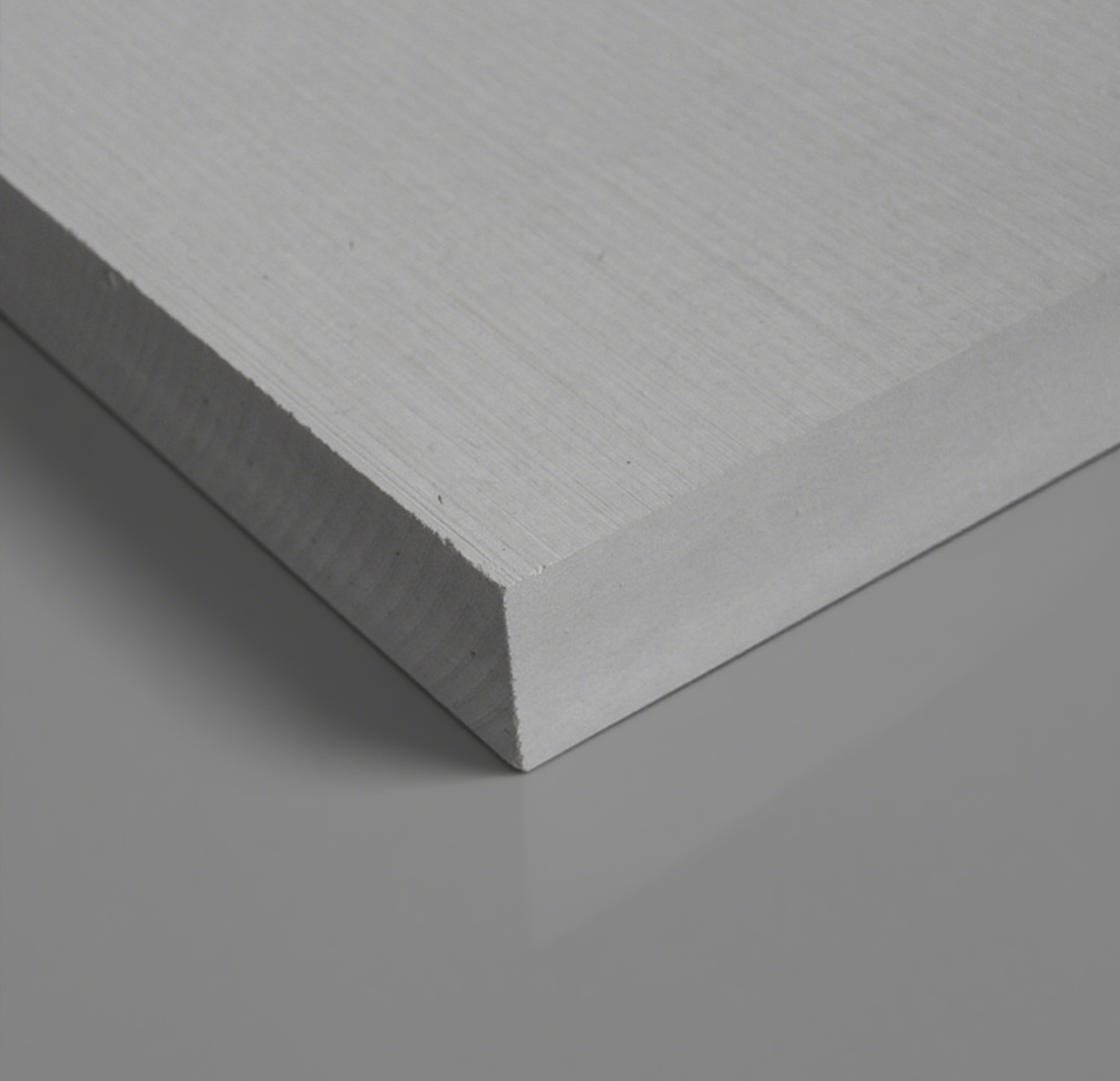

Polycrystalline Fiber Board is one typical materials used for glass furnaces:

This specialized insulation material is designed for extreme high-temperature applications in glass melting. It offers:

High-Temperature Resistance: Withstands temperatures up to 1800°C, suitable for demanding glass melting processes.

Low Thermal Conductivity: Minimizes heat transfer, ensuring efficient insulation and energy savings.

Lightweight: Reduces the overall weight of the furnace structure, simplifying construction and maintenance.

Excellent Thermal Shock Resistance: Withstands rapid temperature changes without cracking or deteriorating.

Chemical Stability: Resists reactions with molten glass and other chemicals present in the furnace environment.