Global

Jun 24 , 2025

A deep bed filter system for molten aluminum is a critical piece of equipment in the aluminum casting industry, designed to remove inclusions and impurities from the molten metal before it solidifies. These impurities, which can include oxides, nitrides, borides, and other non-metallic particles, can significantly degrade the mechanical properties, surface finish, and overall quality of the final aluminum product. By effectively filtering the molten aluminum, deep bed filter systems help to produce cleaner, higher-quality castings, reduce defects, and improve process efficiency.

Here are the different parts of a typical deep bed filter system for molten aluminum and an introduction to their functions:

· Filter Box/Housing:

o Function: This is the primary containment vessel for the entire filtration system. It is typically constructed from refractory materials capable of withstanding the high temperatures and corrosive nature of molten aluminum. The filter box provides structural support and insulation, ensuring that the molten metal maintains its temperature during the filtration process. It also directs the flow of molten aluminum through the filter media.

· Filter Media (Deep Bed):

o Function: This is the core of the filtration system where the actual removal of impurities takes place. The deep bed consists of a granular refractory material, often alumina or silicon carbide, packed to a specific depth. The individual grains of the media create a tortuous path with numerous small pores. As molten aluminum flows through this bed, the impurities are trapped through various mechanisms including mechanical entrapment, impingement, and often, chemical adhesion to the surface of the filter media. The "deep bed" aspect refers to the substantial thickness of the media, allowing for significant contaminant loading capacity and high filtration efficiency.

· Pre-Filter (Optional but Recommended):

o Function: Sometimes placed upstream of the deep bed, a pre-filter (often a coarse ceramic foam filter) serves to remove larger inclusions and protect the more delicate deep bed from premature clogging. This extends the lifespan of the deep bed filter and improves overall filtration efficiency.

· Molten Aluminum Inlet/Pouring Spout:

o Function: This is where the unfiltered molten aluminum enters the filter box, typically from a furnace or holding ladle. The design ensures a steady and controlled flow of metal into the system.

· Molten Aluminum Outlet/Launder:

o Function: After passing through the filter media, the now-cleaned molten aluminum exits the filter box and is directed, often via a launder system, to the casting mold or subsequent processing steps.

· Heating System (Optional but Common):

o Function: To prevent the molten aluminum from solidifying within the filter system and to maintain the desired casting temperature, many deep bed filters incorporate an auxiliary heating system. This can involve electric resistance heaters, gas burners, or induction heating coils integrated into the filter box.

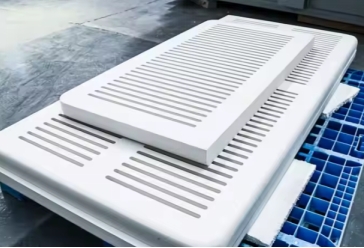

· Lining/Refractory Materials:

o Function: The internal surfaces of the filter box are lined with specialized refractory materials (e.g., dense castables, bricks, or ceramic fiber) that are resistant to thermal shock, high temperatures, and chemical attack from molten aluminum. These linings ensure the integrity and longevity of the filter system.

· Support Structure/Frame:

The support structure can be made from different kind of materials, such as High density calcium silicate boards, silicon carbide materials.

o Function: This provides the necessary structural integrity to hold the entire filter system, including the filter box, filter media, and molten aluminum, in place during operation.

In summary, a deep bed filter system for molten aluminum operates by passing the molten metal through a packed bed of granular refractory media. This process physically and chemically removes impurities, resulting in cleaner aluminum that leads to superior product quality, reduced defects, and enhanced productivity in aluminum casting operations.