Global

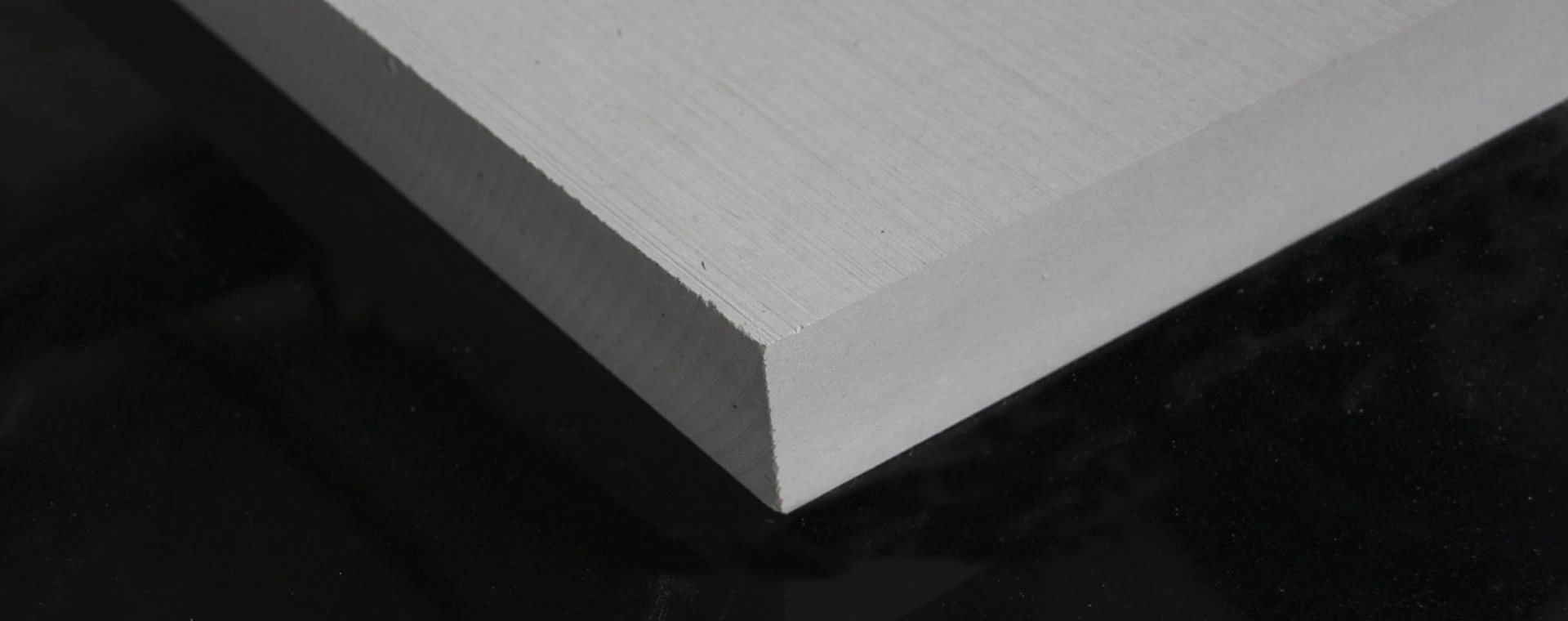

How Ceramic Fiber Insulation Improves Energy Efficiency

Ceramic fiber insulation minimizes heat loss, leading to significant energy savings in high-temperature processes.

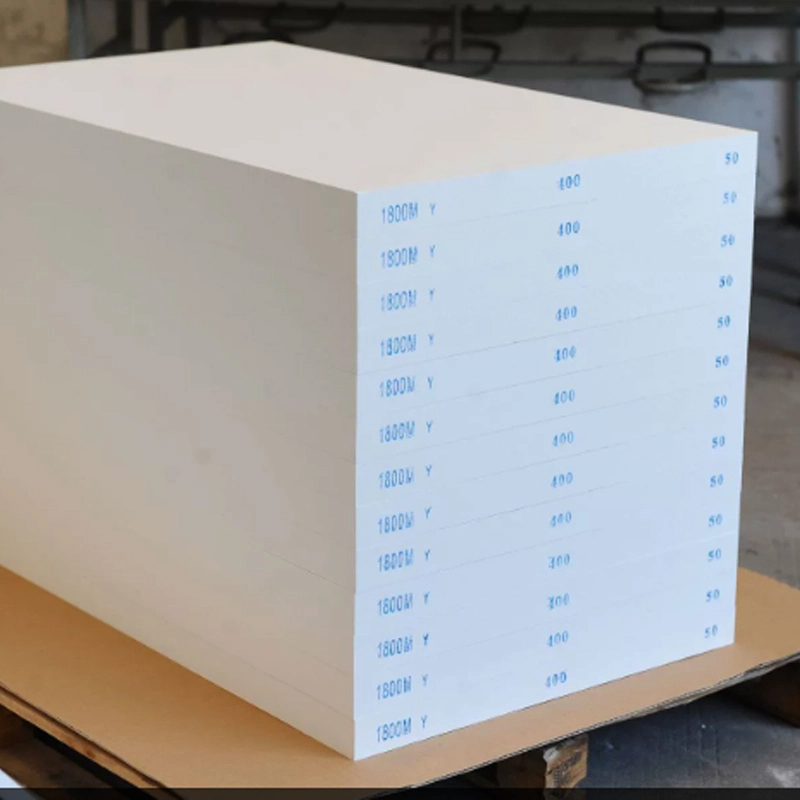

Reduces Heat Loss: Maintains consistent temperatures in industrial equipment.

Lowers Fuel Consumption: Improves furnace efficiency by reducing heat escape.

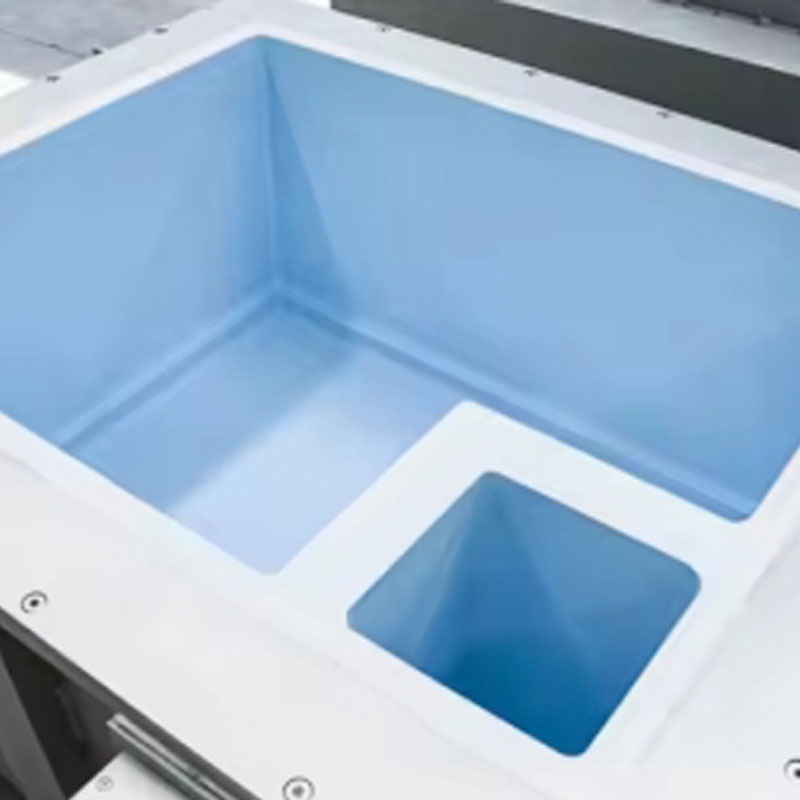

Fast Thermal Recovery: Heats up and cools down quickly, saving operational time.