Global

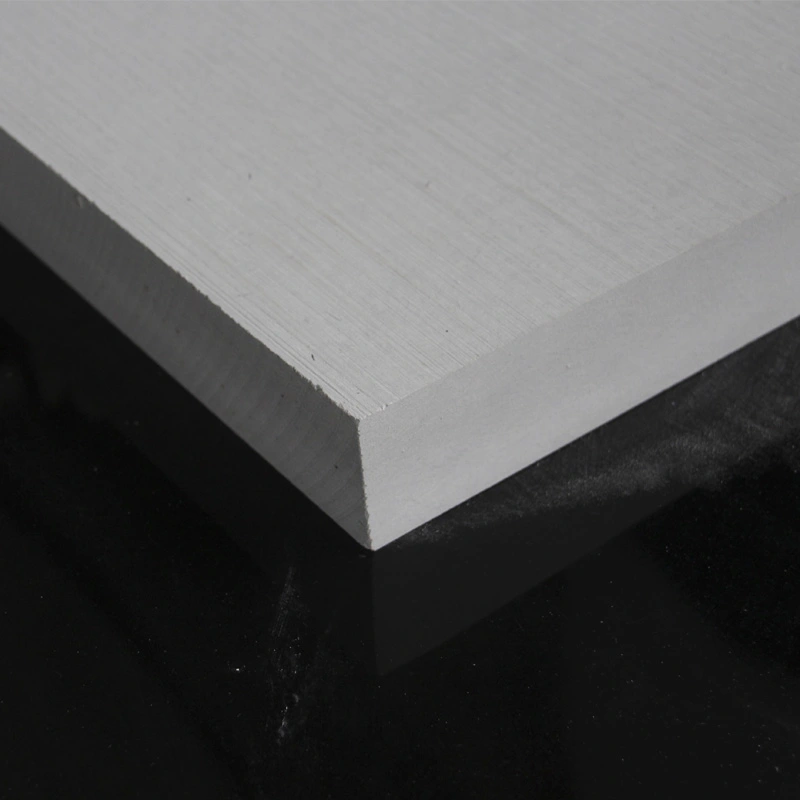

What Is the Expected Lifespan of High Density Calcium Silicate Board?

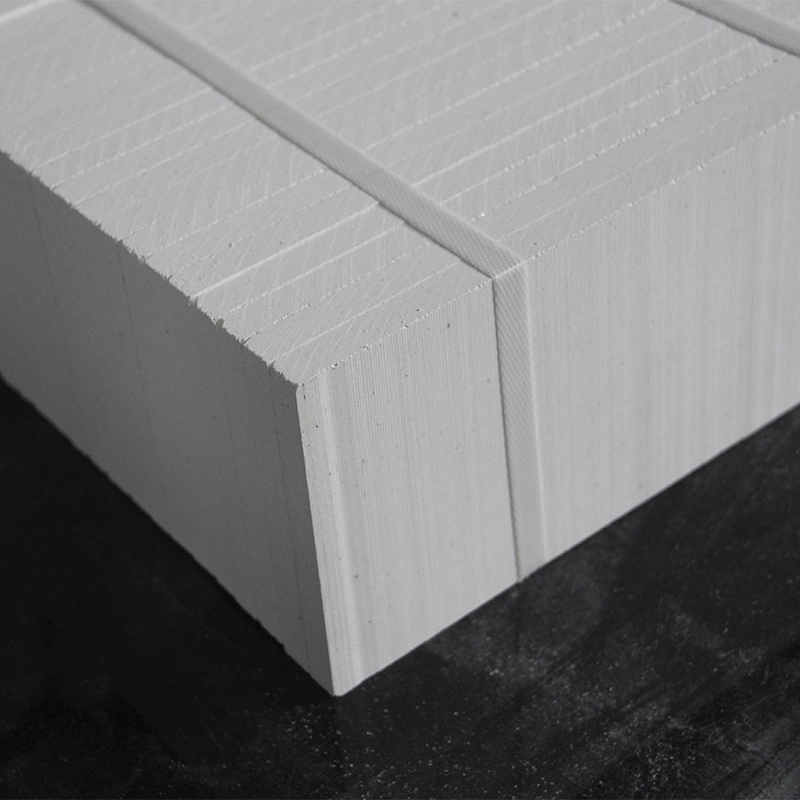

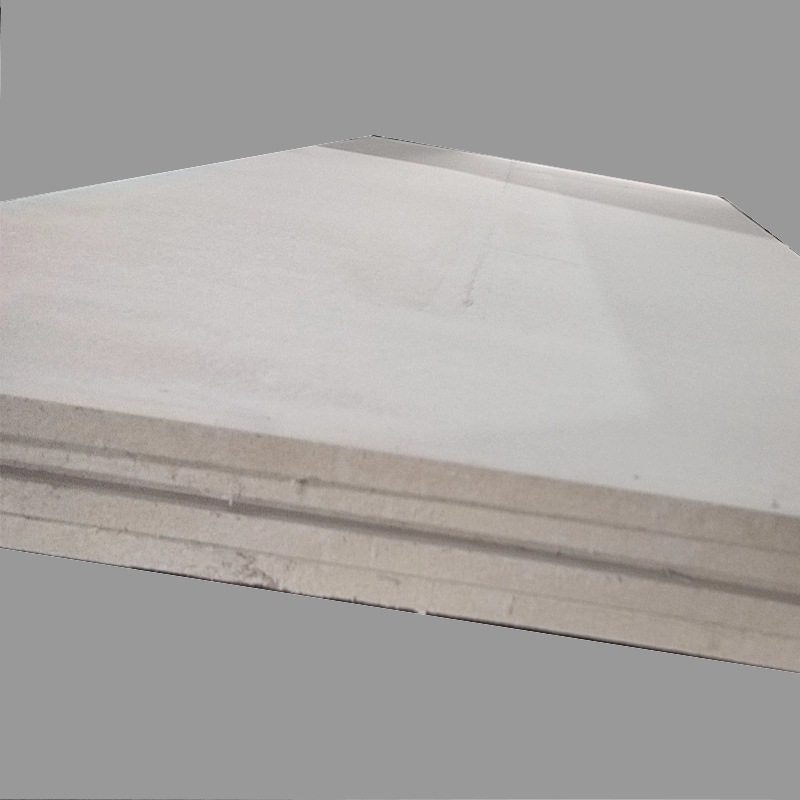

With proper installation and maintenance, High Density Calcium Silicate Boards can last for several decades, typically ranging from 30 to 50 years or more. Their longevity is attributed to their robust composition, which includes a mixture of calcium and silica reinforced with fibers, making them highly resistant to wear and tear. These boards are also impervious to moisture, mold, and pests, which further extends their lifespan. Regular inspections and minor maintenance, such as sealing any cracks or reapplying protective coatings, can help maximize their durability and ensure they remain in optimal condition for many years.