Global

Jun 17 , 2025

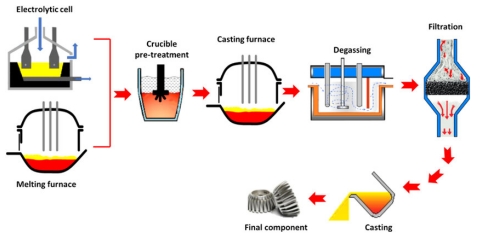

Impurities in high-purity ingots, including inclusions, hydrogen, and alkali metal elements such as sodium (Na), calcium (Ca), and lithium (Li), can all negatively affect the purity of aluminum melt, the quality of ingots, and the quality of final aluminum or aluminum alloy semi-finished products and products. This article will discuss how to effectively remove these key impurities to ensure the high purity of ingots.

High-purity ingots play a crucial role in the manufacturing process of aluminum or aluminum alloys. By removing key impurities such as inclusions, hydrogen, and alkali metal elements, the purity of aluminum melt can be significantly improved, thereby ensuring the quality of ingots and final products. Such high-purity ingots are not only vital for high-end fields such as aerospace but also of great significance for enhancing the competitiveness of the entire aluminum industry chain. Therefore, the development of high-purity ingots is particularly urgent and necessary.

Excessive inclusions or hydrogen content may cause surface bubble defects during heat treatment, seriously affecting product quality.

2. High hydrogen content (measured in cm³/100g-Al) or inclusion content (measured in mm²/kg-Al) can not only form subsurface hydrogen pores but also lead to a decline in material mechanical properties after multiple heating and hot working processes.

3. Trace lithium impurities can accelerate the oxidation process of aluminum melt.

4. The addition of trace calcium will increase the hydrogen content and inclusion content in aluminum melt.

5. The presence of sodium may lead to embrittlement of aluminum alloys and oxide-related issues.

(1) Removal of Alkali Metals is Crucial

The application of in-furnace granular refining agents is a key step to effectively reduce the content of alkali metals.

(2) Online Degassing Technology is Indispensable

Online degassing can further ensure the high purity of ingots.

Challenges in In-Furnace Refining

Although methods such as chlorine gas, chloride salts, or fluoride salts may be used during in-furnace refining, the content of impurities such as hydrogen and inclusions in the aluminum melt often fails to meet the expected quality standards.

2. Process Principles

In the in-furnace refining process, to ensure that the aluminum melt meets the expected quality standards, it is necessary to degas the aluminum melt and filter out inclusions, which is usually completed on the launder.

3. Online Degassing Technology

Online degassing involves installing a heat-insulated and airtight container on the launder (i.e., between the furnace and the casting system). Inside this container, a graphite rotor continuously generates a large number of small bubbles. These bubbles carry hydrogen or impurities to the top of the container through buoyancy, thereby achieving the removal effect. The gas used for bubbling can be a mixture of chlorine and nitrogen or pure argon.

4. Chlorine Degassing Technology

Chlorine degassing technology is known for its high efficiency. However, when treating aluminum-magnesium alloys, it produces tiny magnesium chloride particle inclusions. If not properly handled, these inclusions may enter the final cast products. Although mechanical or physical filtration systems can be used for removal, these methods may not completely eliminate them. Therefore, tubular filtration and deep-bed filtration technologies have been successively developed and put into use to more effectively address this issue.

5. Degassing Efficiency

Currently, online degassing systems are quite mature, with a degassing efficiency of approximately 50%. Degassing efficiency can be calculated using a formula: [(hydrogen content before degassing - hydrogen content after degassing) / hydrogen content before degassing] × 100%. This formula helps us understand the performance of the degassing system.

6. Potential Impact of Degassing Tanks

While ensuring degassing efficiency, we must also pay attention to other impacts that degassing equipment may bring, especially potential side effects. These side effects include the generation of aluminum dross, the formation of inclusions, and the quality of residual aluminum melt in the tank-shaped container.

Positive Role of Degassing Tanks

An excellent hydrogen degassing system not only does not cause inclusion problems but can effectively remove inclusions from the aluminum melt. Meanwhile, the degassing system is also a powerful tool for removing fine inclusions. When considering aluminum melt treatment, we should further explore the feasibility of online filtration.

2. Importance of Online Filtration

Although in-furnace treatment is important, the aluminum melt may generate or carry inclusions and hydrogen during transportation, especially in online launders and degassing systems. Therefore, setting up an online filtration system has become a crucial final line of defense to ensure that impurities do not enter the cast billet.

3. Selection of Filtration Methods

To effectively remove inclusions and hydrogen from aluminum melt, commonly used filtration systems mainly include three types: ceramic foam filter plates (CCF), cartridge filtration, and deep-bed filtration. Each of these filtration methods has its characteristics, and the selection needs to be comprehensively considered according to actual conditions.

4. Selection of Filtration Systems

In the aluminum melt treatment process, choosing an appropriate filtration system is of great importance. The three filtration methods—ceramic foam filter plates (CCF), cartridge filtration, and deep-bed filtration—each have their unique advantages and applicable scenarios. Therefore, in specific applications, it is necessary to comprehensively consider product quality requirements, production line design, and the characteristics of various filtration methods to make the best choice.

5. Ceramic Foam Filter Plates

Ceramic foam filter plates have a standard thickness of 2 inches (5.08 cm). Common pore size specifications include 30ppi, 40ppi, 50ppi, 60ppi, and 70ppi, where ppi stands for the number of pores per square inch. It is worth noting that the finer the pore size, the higher the filtration efficiency, but the lower the flow rate of aluminum melt.

Additionally, the efficiency of filter plates is affected by various factors, such as the size of inclusions, the flow rate of aluminum melt, and the pore size. For example, a 30ppi filter plate can intercept approximately 60% of 30-micron inclusions, while a 70ppi filter plate can almost completely remove solid inclusions of 30 microns and above. However, for tiny inclusions below 10 microns, the filtration effect of foam filter plates is relatively weak, and other filtration methods or highly efficient degassing systems may need to be combined for processing.

6. Two-Stage Filtration

The two-stage filtration system uses double-layer ceramic foam filter plates, where the first layer is a filter plate with a larger pore size and a correspondingly larger area, and the second layer is a filter plate with a smaller pore size and a smaller area. For example, the first layer uses a 30ppi filter plate, and the second layer uses a 50ppi filter plate, aiming to achieve a flow rate equivalent to that of 30ppi while improving filtration efficiency to 50ppi or higher. This two-stage filtration method is economical and versatile, effectively removing various inclusions in aluminum melt.

However, two-stage filtration also has limitations, especially for small particles (such as 10 microns or below), where its filtration efficiency is relatively low.

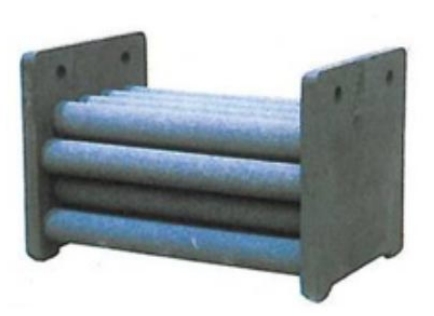

7. Cartridge Filtration

(1) In the production of high-purity aluminum or aluminum alloy materials, deep-bed filtration systems or cartridge filtration systems are often preferred. Cartridge filter materials have tiny pore sizes and can effectively filter micron-level inclusions. When aluminum melt passes through ceramic tubes, inclusions inside are intercepted outside the tubes, ensuring the purity of the aluminum melt. However, cartridge filtration systems and filter materials have relatively high costs and require a large floor space. In addition, the system requires that the continuously used aluminum melt must be of the same alloy; otherwise, the filtration effect may be affected.

(2) To extend the service life of cartridge filter materials, they can be used in combination with foam filtration systems. First, large-sized inclusions in the aluminum melt are removed by foam filter plates, and then tiny-sized inclusions are removed by cartridge filtration. This combined use typically allows cartridge filter materials to continuously filter aluminum melt of the same alloy up to 200 tons or more.

(3) Cartridge filtration systems are particularly suitable for producing aluminum rods with purity close to Grade 1, such as ingots for manufacturing photosensitive drums, ultra-thin aluminum foil, high-anode-quality products, and 3C products. These high-purity ingots can significantly improve the extrusion production speed and the surface quality of extruded products during subsequent processing.