Global

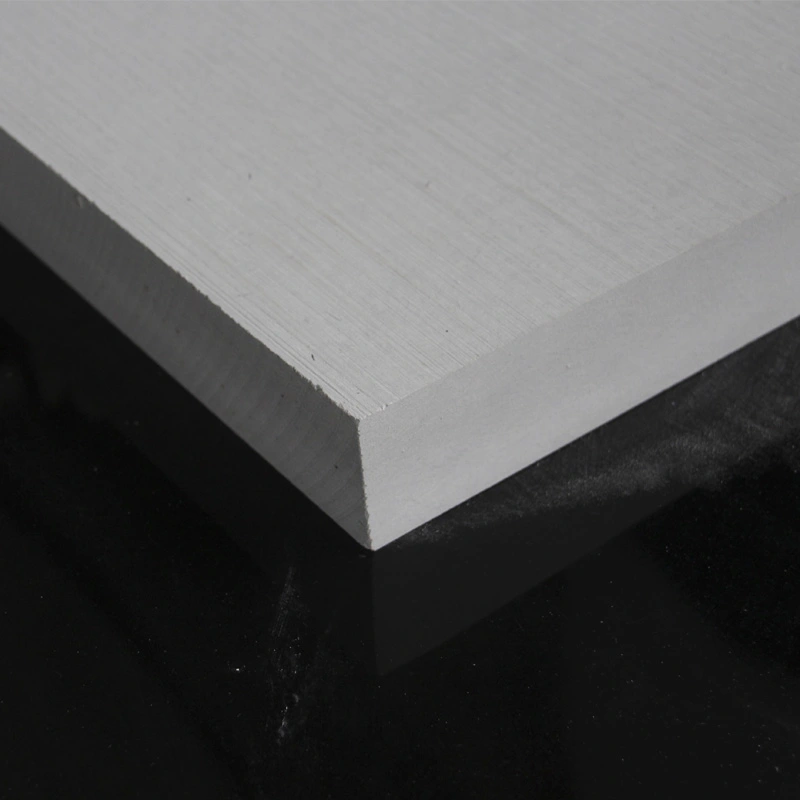

How Are Calcium Silicate Parts Machined? (Process & Tolerances)

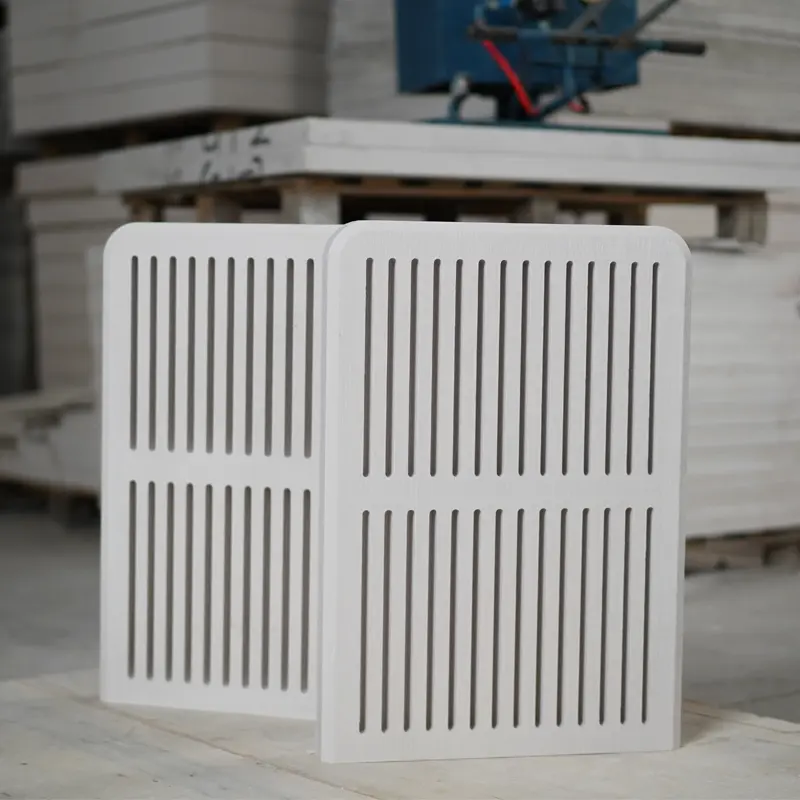

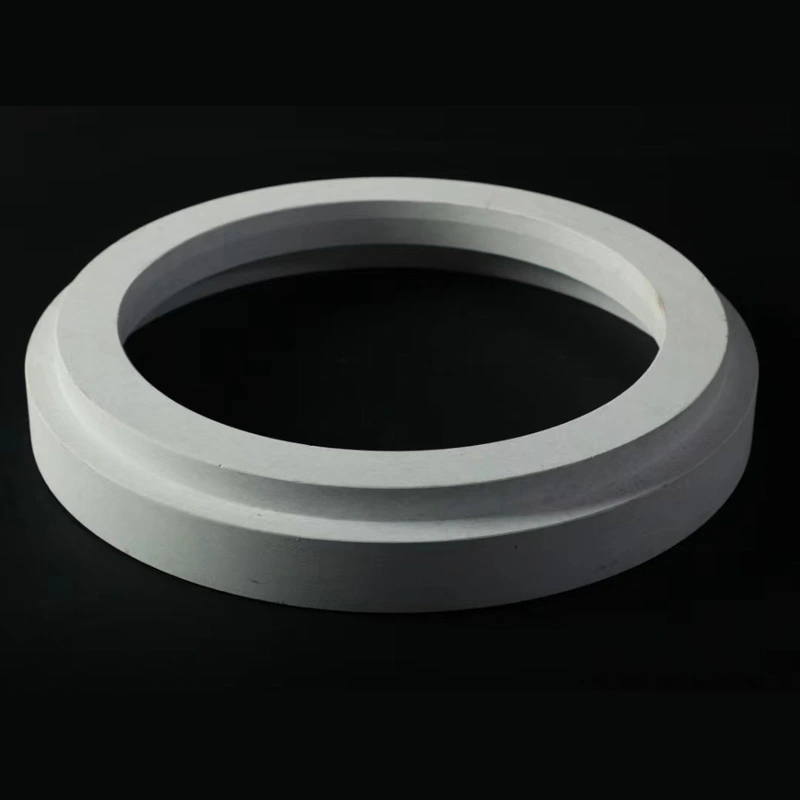

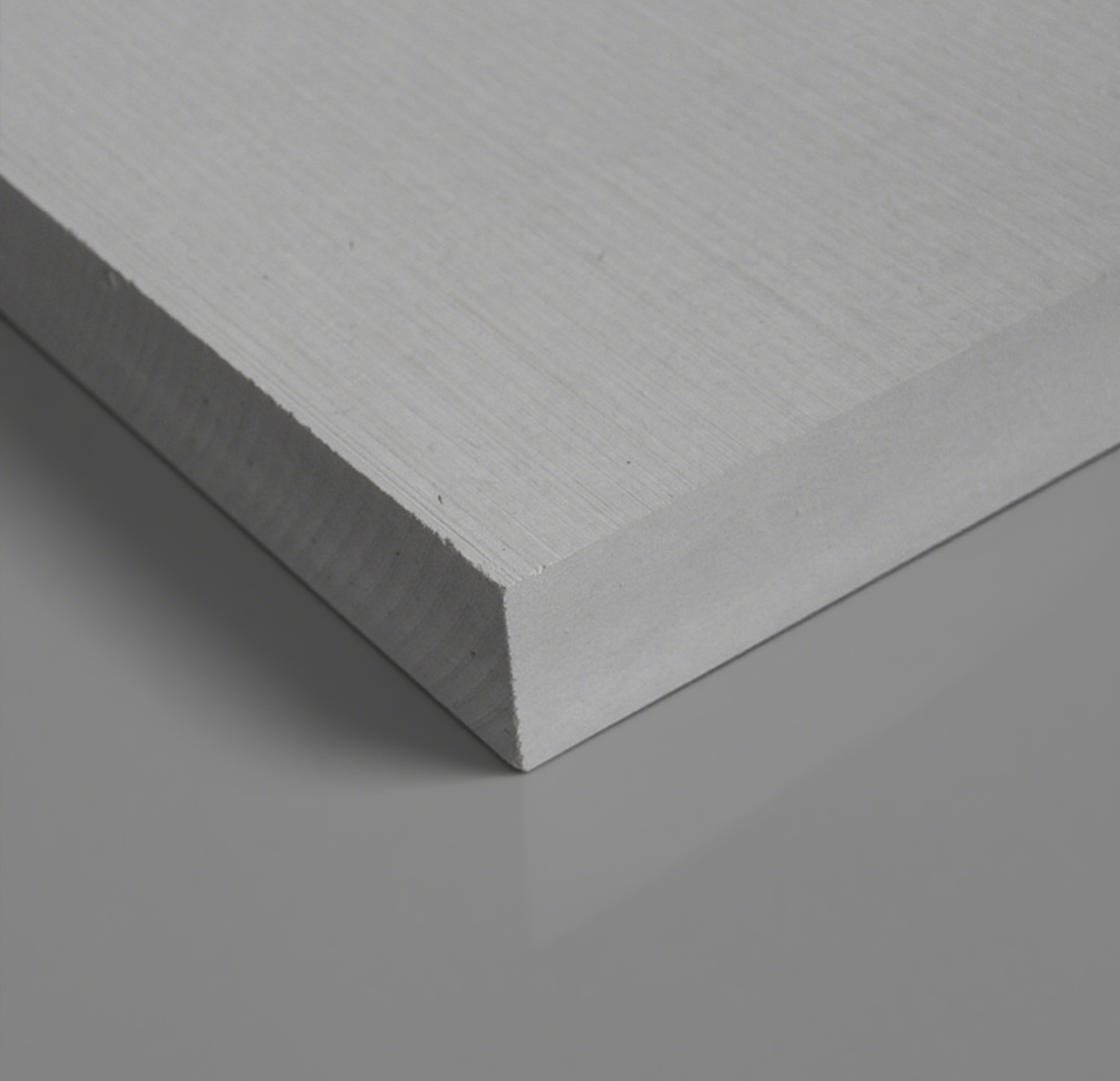

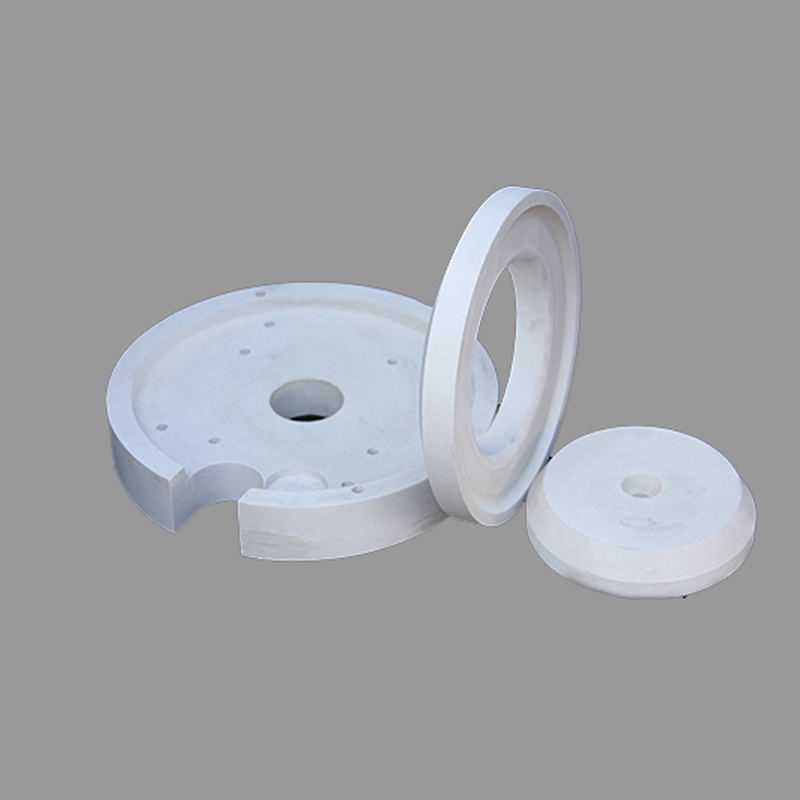

Calcium silicate is machined using diamond-coated CNC tools to prevent chipping. The process includes:

CAD Design – Optimized for manufacturability (DFM)

Precision Machining – CNC milling, lathing, or grinding

Post-Processing – Polishing, coating, or heat treatment