Global

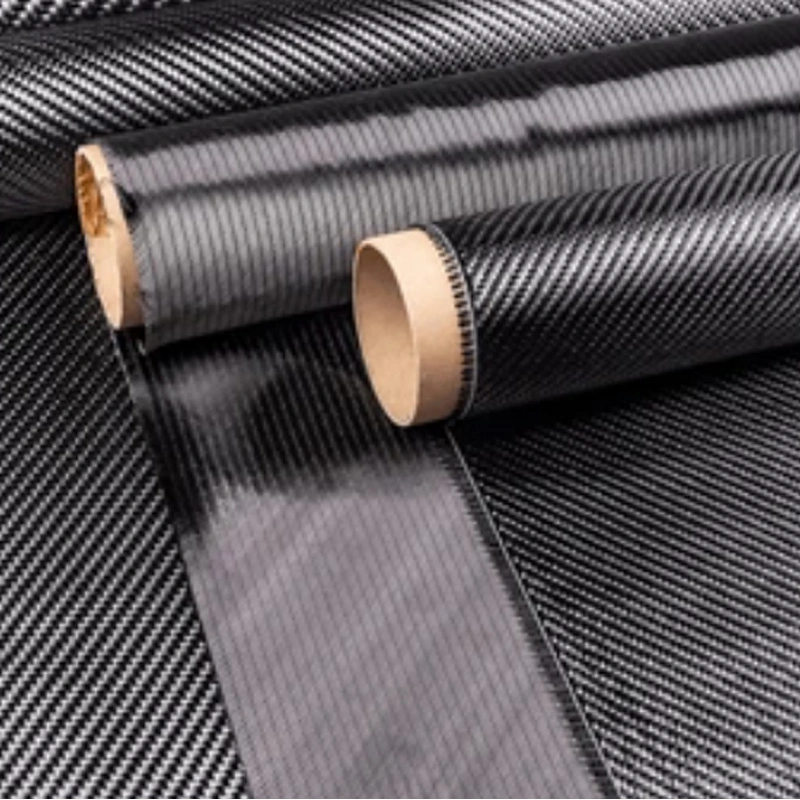

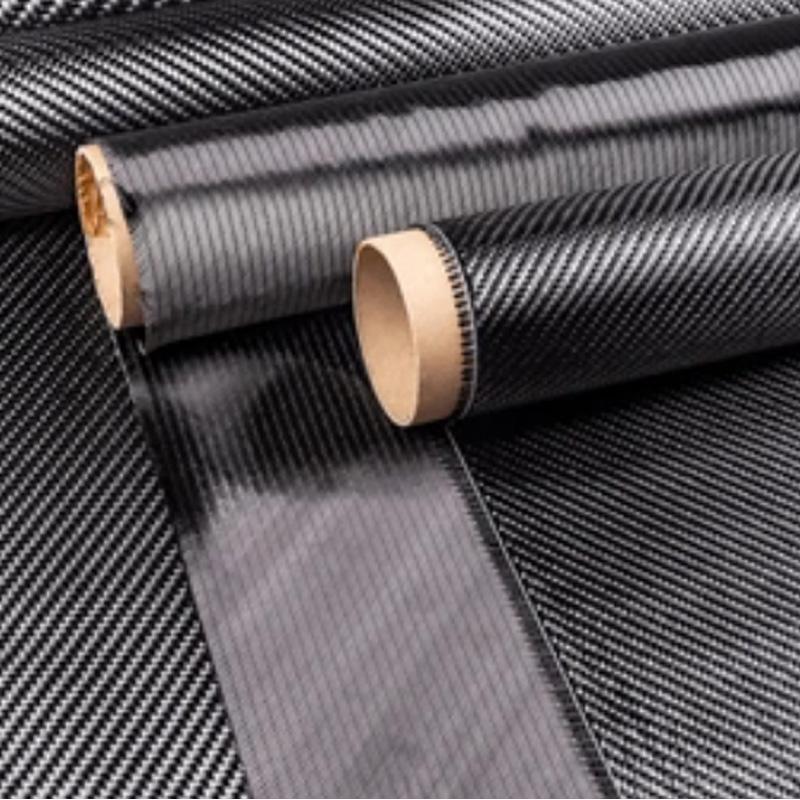

How is carbon fiber made?

The manufacturing process involves:

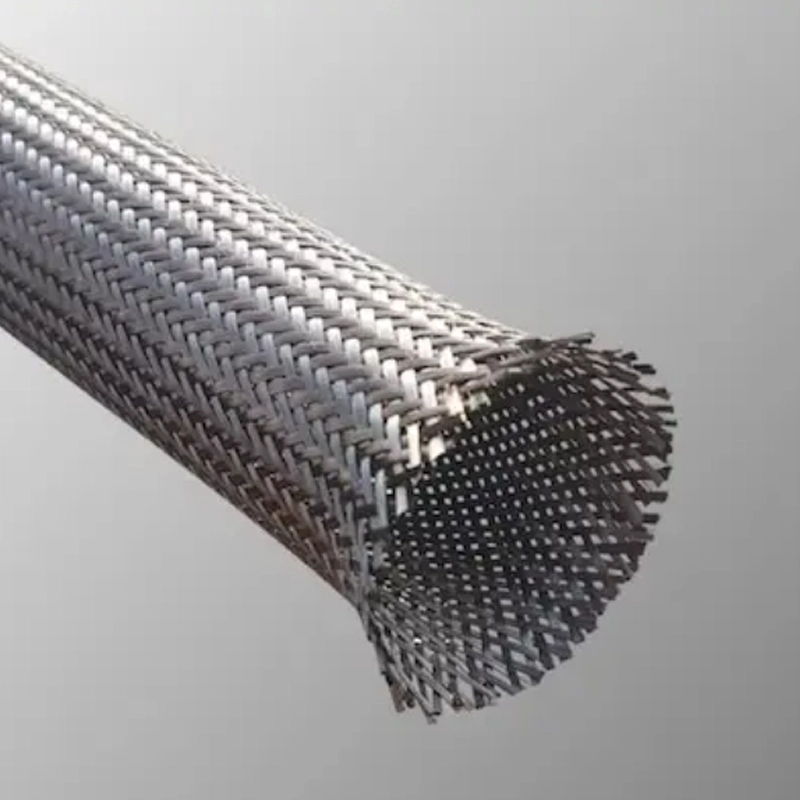

Precursor production: PAN (polyacrylonitrile) or pitch fibers are spun into strands.

Oxidation: Heated to 200–300°C in air to stabilize the fibers.

Carbonization: Heated to 1,000–3,000°C in inert gas to remove non-carbon atoms.

Surface treatment: Fibers are coated to improve resin adhesion.

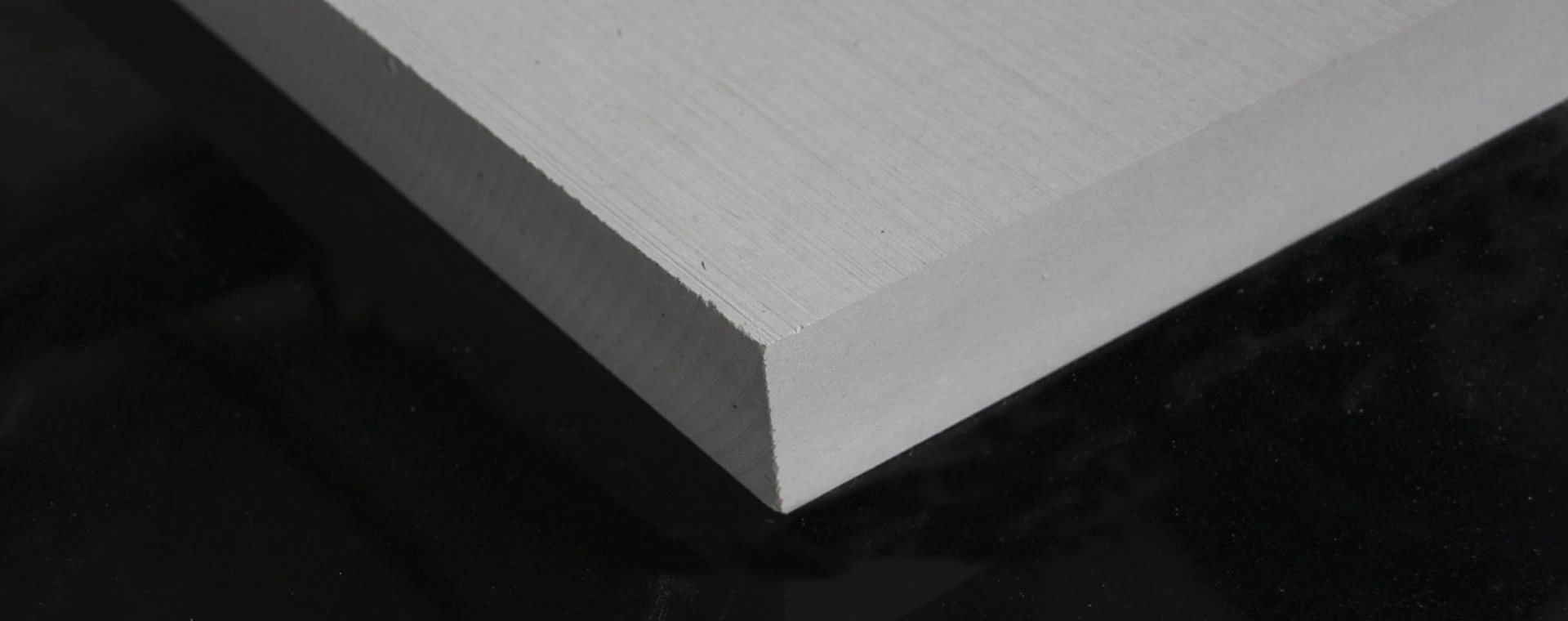

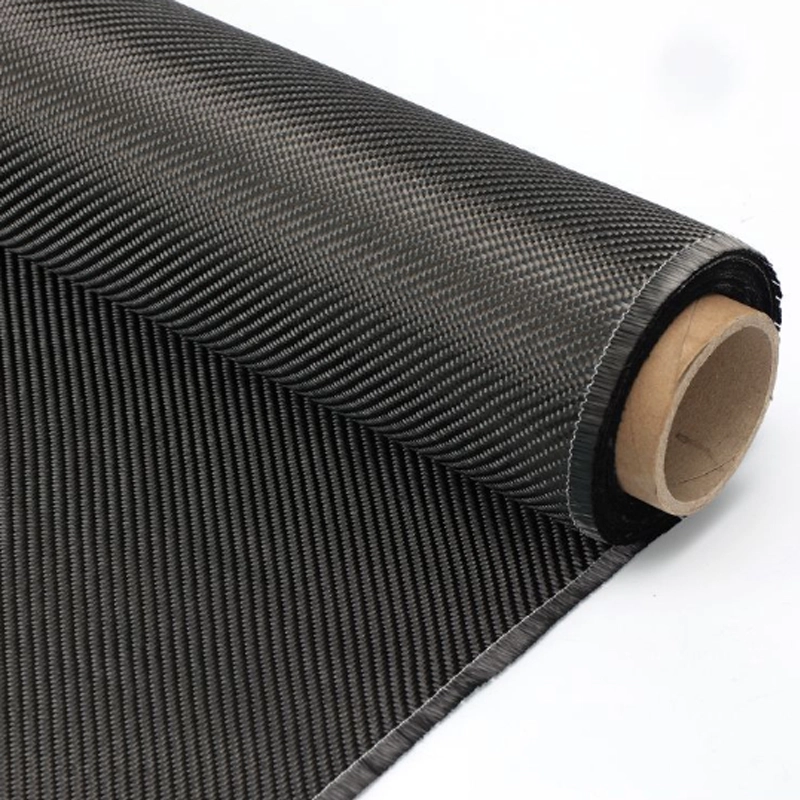

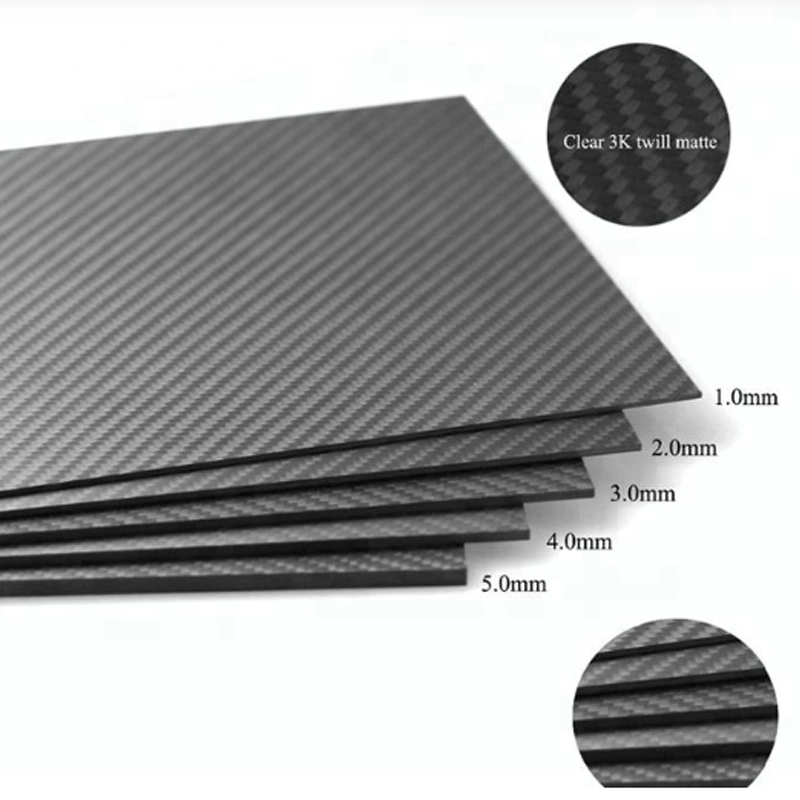

Composite formation: Fibers are layered with resin and cured under heat/pressure (e.g., autoclave molding).