Global

May 06 , 2018

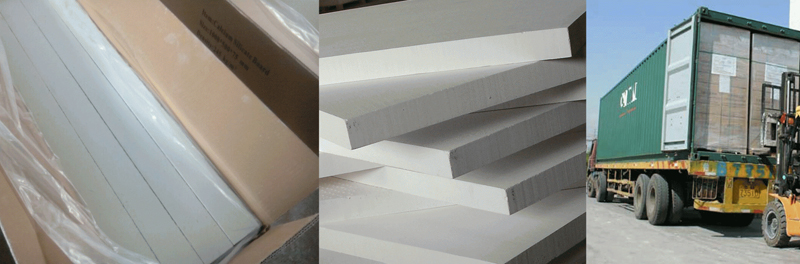

Calcium silicate board is an asbestos-free thermal insulation material that can handle temperatures up to 1100 degrees C. It has low thermal conductivity, high strength, is lightweight and is easy to cut. Calcium Silicate Board is commonly used as furnace backup insulation in the steel, ceramic, cement and glass industries or for passive fire protection of structural steel. Its high compresive strength and insulation coefficient makes it ideal for use as sub-floor insulation for Wood Fired Ovens.

While many of the oven plans available online focus on insulating the dome of the oven, a few ignore the need to insulate underneath the floor of the oven, and suggest using a thick layer of sand or similar. The problem with this approach is that the heat in the floor of the oven will be passed straight through into your concrete hearth slab. This presents a host of problems.

You're heating reinforced concrete which is not designed to handle high temperatures.

The support slab is exposed to air which will absorb this heat and cool your oven.

It increases the thermal mass in the oven floor by the weight of your supporting slab.

All this adds up to an oven floor that can take more than 4 hours to heat up, which is compounded by the fact that the floor will rapidly cool due to the air absorbing all the heat out of it. This means that the top of your pizza will start to burn long before you can get the base properly cooked. Calcium Silicate Board is the perfect engineering solution to the problem; high compressive strength to take the weight of the oven, easy to cut, exceptionally low thermal conductivity and it’s rated to over 1000 degrees C. With 50mm of CalSil board underneath your oven, the floor is well insulated and will hold its temperature for hours.

Dimensions: 1000x500x50mm

Density: 250-300 kg/m3

Thermal Conductivity: 0.056W/m.K

Max Service Temperature: 1050 degrees C