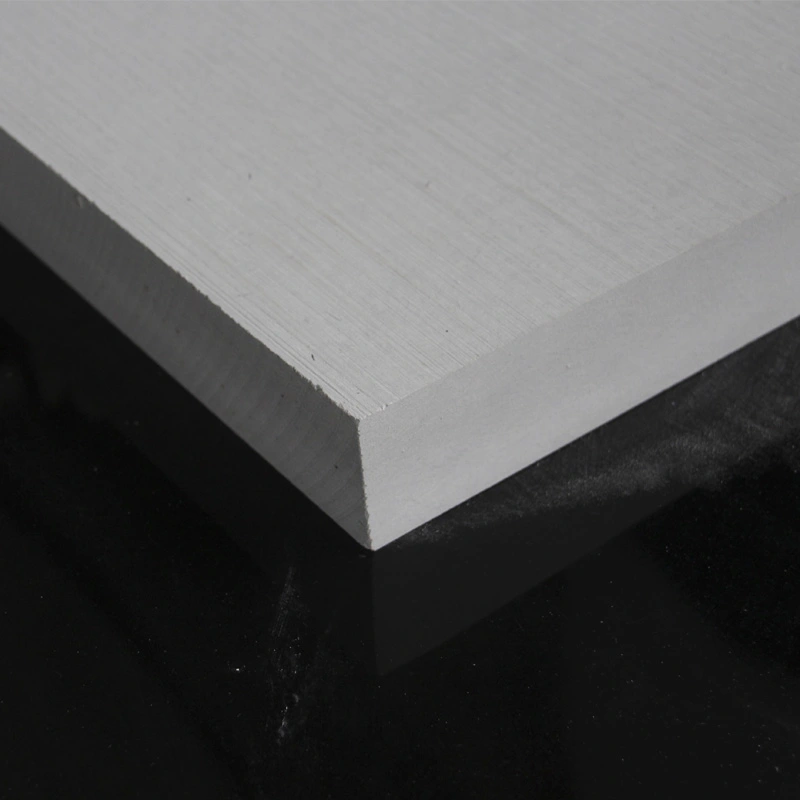

Alumina – Silica insulation [ceramic fiber insulation ] include different shapes and temperature grades ranging from 2300F to 2600F [ for ultra high temperature insulation material, please refer to ultra high temperature insulation introduction page ]

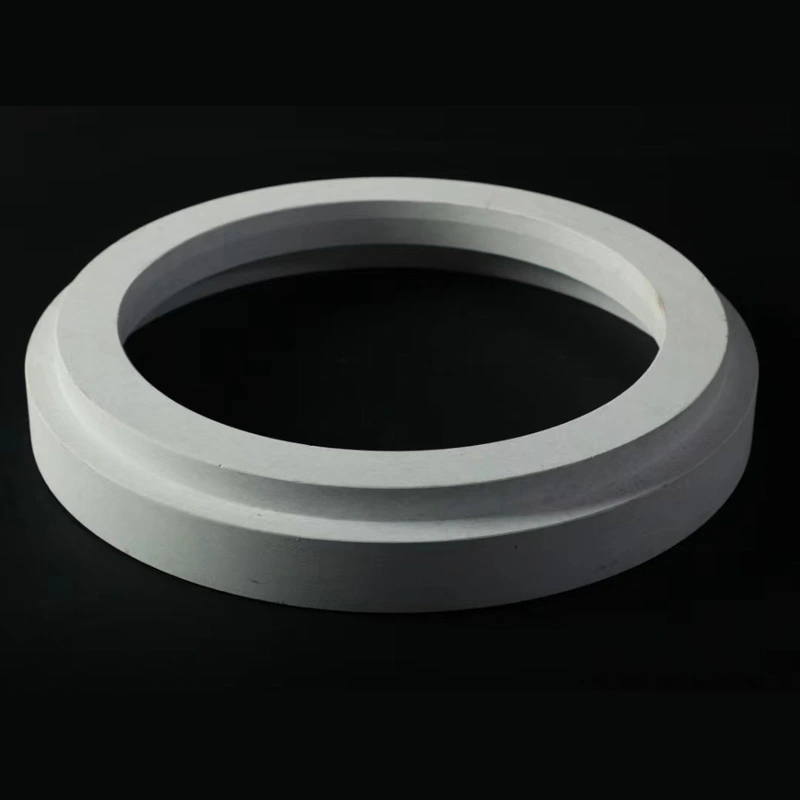

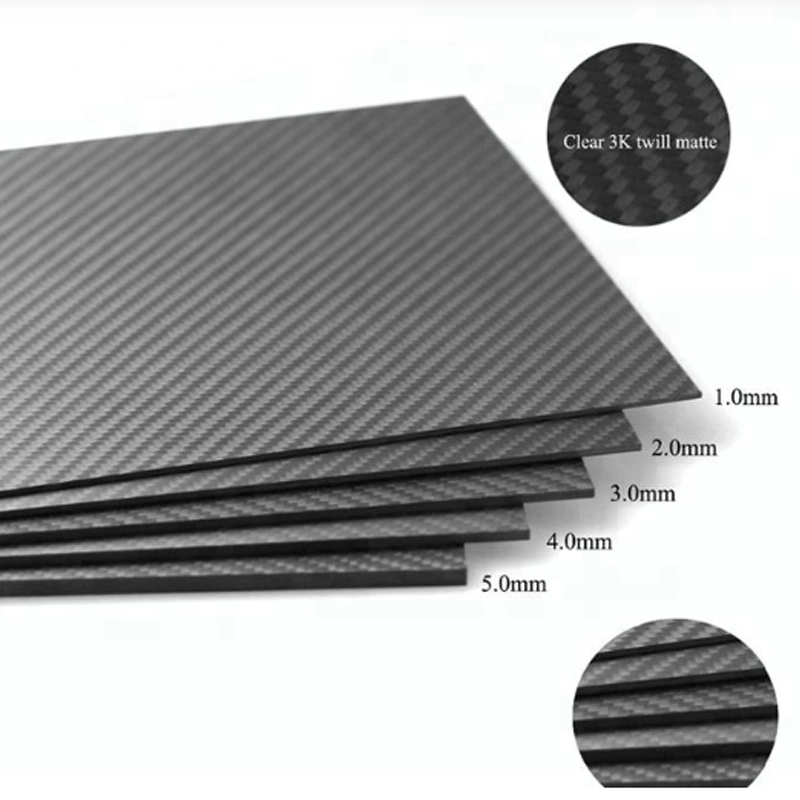

Alumina Silica Insulation Blanket, Alumina Silica Insulation Board, Bulk Fibers, Alumina Silica Fiber Modules and Alumina Silica Ropes.

Applications include:

Boiler and Water heater linings for combustion areas

Pipe insulation

Gasketing

Heat Shielding

Fire Protection

Kiln and Industrial furnace linings

Flue liners

Backup insulation for castable, brick, etc.

Burner assemblies, and nozzles

Economical back-up for higher temperature insulation

Usable anywhere high temperature insulation is required