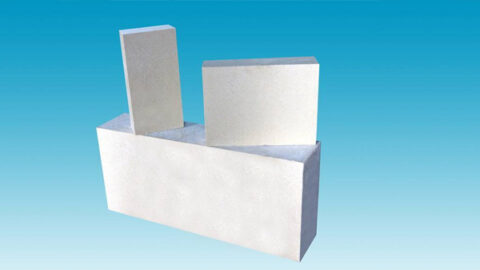

Corundum Brick

Carefully defined additives of raw materials with chromium and zirconium content improve the service life span of the corundum bricks against CaO-FeO-SiO2 slags and glass melts, and are used in waste incineration plants ...

- Corundum bricks of ≥ 90% Al2O3 are manufactured using synthetic fused corundum and sintered corundum and finely grained highly aluminous raw materials with ceramic and chemical bonding. Sophisticated bricks and large blocks with 65 % to 99 % Al2O3 content are shaped by vibration shaping or slip casting and fired at high temperatures in modern firing plants, apart from compression shaping on modern hydraulic presses.

- Carefully defined additives of raw materials with chromium and zirconium content improve the service life span of the corundum bricks against CaO-FeO-SiO2 slags and glass melts, and are used in waste incineration plants and blast furnaces, and melters for colored glass and glass fiber. Corundum bricks with a 99 % Al2O3 content are also resistant at high operating temperatures in CO atmospheres and hydrogenous atmospheres.

- They are therefore used in furnaces for the chemical and petrochemical industry under strongly reducing conditions. The precondition for an optimal and appropriate choice of a brick quality within the balance of prices and terms and conditions is to review all detailed knowledge about the kind of application with the customer.

Free Tab Content