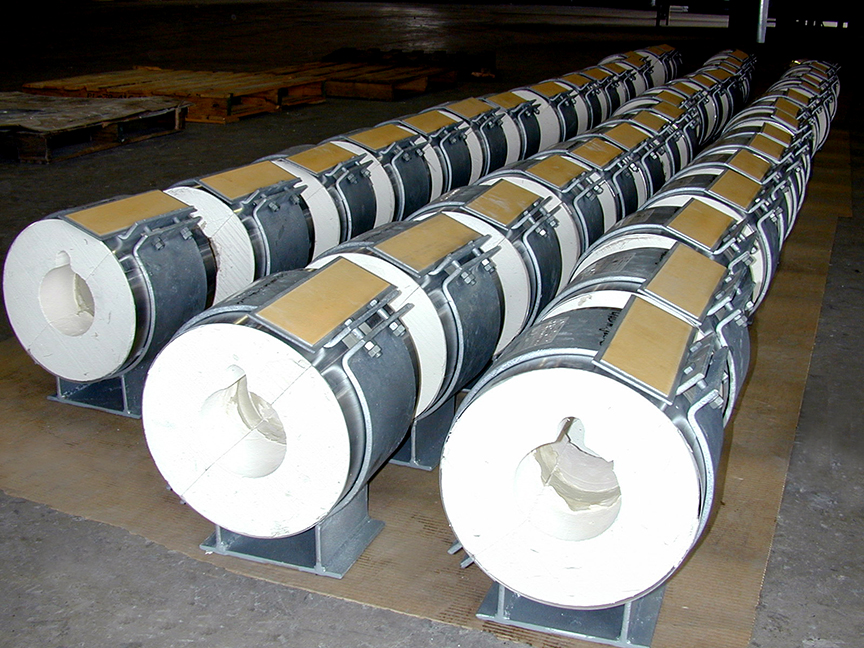

Calcium silicate pipe cover insulation

Calcium silicate pipe cover and block is typically applied in chemical plants, refineries, and steam electric power plants. Due to its high compressive strength (greater than 100 psi) ...

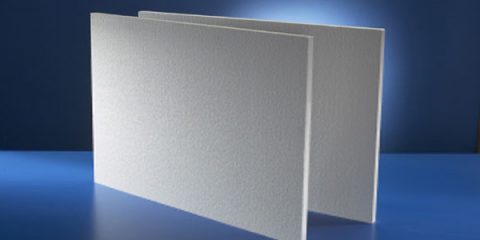

Calcium silicate pipe cover is used to insulate high-temperature pipes and equipments and for fire endurance applications. It is manufactured in three different forms: preformed block, preformed pipe, and board. It is noted for its high compressive strength, corrosion-inhibiting properties, and high-temperature structural integrity – 1,200°F (Type I, for pipe and block) or 1,700°F (Type II, fire endurance boards).

Calcium silicate pipe cover and block is typically applied in chemical plants, refineries, and steam electric power plants. Due to its high compressive strength (greater than 100 psi), high flextural strength (greater than 50 psi), and resistance to damage from tumbling, plus its ability to maintain those properties over time up to its rated 1,200°F, calcium silicate can withstand considerable physical abuse without loss of insulating efficiency. In addition, calcium silicate can withstand vibration induced by high-temperature steam flow around internal pipe obstructions, such as valve internals, measuring devices, and flow restriction orifices.”

ADVANATAGES:

- Guards pipe and equipment surfaces against corrosion

- Excellent resistance to breakage and physical abuse

- No binders to burn out; No loss of insulation integrity

- Excellent thermal performance to 1200°F

- Superior thermal performance from 450°F to 1200°F

- Resistant to mold growth

APPLICATIONS:

Because of its low thermal conductivity, durability, compressive strength and corrosion inhibiting properties, it is the preferred product for application on high temperature piping and equipment. 650°C calcium silicate pipe cover and block is especially recommended for use in the petrochemical, power generation and process industries where piping and equipment operating up to 1200°F. The corrosion inhibiting properties are not diminished by heating and cooling so the corrosion protection will continue for the life of the product.

SPECIFICATION :

| Item | Unit | NRCL-

HTB-200 |

JIS A-9510

No.1-22 |

ASTM C-533

No.2 |

| Density | Kg/m3 | <=240 | <=220 | <=240 |

| Service

Temperature |

°C

|

<=1000

|

<=1000 | <=871

|

| Compressive

Strength |

Mpa

(kgf/cm2) |

>=0.84

(>=8.56) |

>=0.414

(>=4.22) |

|

| Thermal

Conductivity |

W/m.k

(70±5°C) |

<=0.060 | <=0.062 | <=0.095

(204°C) |

| Linear Shrinkage

(982°C 24 h) |

% | <=2.0 | <=2.0 | <=2.5 |

| Bending

Strength |

Mpa

(kgf/cm2) |

>=0.45

(>=4.59) |

>=0.30

(>=3.1) |

>=0.310

(>=3.162) |

| Standard size-Pipe Cover | |

| Inside Diameter | 16mm(1/4”)-4800mm(188”) |

| Length | 600mm 610mm |

| Thickness | 25mm 30mm 40mm 50mm 60mm 65mm 70mm 75mm 80mm 90mm |

Except the calcium silicate pipe cover, we can supply also the calcium silicate flat blocks and scored blocks, pipe fitting, flanges, valves, calcium silicate powders, customized shapes by CNC machine.

PICTURES :

Equivalent and similar products over the world for reference :